Advanced Filters

Category

Refurbished Damark STR16 Shrink Tunnel

Refurbished Damark STR16 Shrink Tunnel

The Damark STR16 is a durable, Canadian-built shrink tunn...

Details

Refurbished Emplex 55BV5/CZ Band Sealer with Conveyor – Hydro Approved

The Emplex 55BV5/CZ is a continuous band sealer / bag sealer built for fast, consistent, and prof...

Details

Refurbished BEL 505 Semi-Automatic Case Erector

Refurbished BEL 505 Semi-Automatic Case Erector

The BEL 505 is a semi-automatic case erector des...

Details

Damark STB16 Shrink Tunnel

The Damark STB16 is a heavy-duty shrink tunnel designed for consistent, high-quality shrink perfo...

Details

Gerrard Ovalstrapping 415 Automatic Arch Strapper

he Gerrard Ovalstrapping 415 is an automatic arch strapping machine engineered for fast, consiste...

Details

Refurbished 3M 700R Random Case Sealer

The 3M 700R is a fully automatic random case sealer engineered for high-speed, mixed-size carton ...

Details

3M 700R Random Case Sealer

The 3M 700R is a random case sealer designed for high-speed, automatic sealing of cartons of vary...

Details

Damark SMC1620 Semi-Automatic L-Bar Sealer

The Damark SMC1620 is a semi-automatic L-bar shrink sealer designed for precision, reliability, a...

Details

Highlight 2300 T Table 2"

Highlight 2300 T-Table 2" Case Sealer

The Highlight 2300 T-Table is a semi-automatic case formin...

Details

Nestaflex 200 Expandable Conveyor – 24" Wide, Extends 7'–40'

The Nestaflex 200 is a flexible gravity roller conveyor engineered for maximum adaptability and d...

Details

Used Nestaflex 375 Expandable Conveyor – 24" Wide, Expands 6'–16'

The Nestaflex 375 is a used flexible gravity roller conveyor built for maximum versatility and mo...

Details

Refurbished Sealast 50M Uniform Side Belt Case Sealer – 2" Tape, Infeed & Exit Tables

The Sealast 50M is a refurbished uniform side-belt drive case sealer engineered for consistent, s...

Details

Used Nestaflex 175 Flexible Conveyor – 14" Wide, Expands 6'–20'

The Nestaflex 175 is a used flexible gravity roller conveyor designed for quick, adaptable produc...

Details

Refurbished Shanklin A27

Refurbished Shanklin A27 Automatic L-Sealer

The Shanklin A27 is a refurbished automatic L-bar sh...

Details

Shanklin TR-CBL-72, Belt Conveyor Infeed For TR2, 16" x 72"L

Shanklin TR-CBL-72 Belt Conveyor Infeed for TR2 – 16" x 72"

The Shanklin TR-CBL-72 is a belt con...

Details

Better Packages - BetterPack 500 Electric Water-Activated Tape Dispenser

The Better Pack 500 is a workhorse dispenser built for speed, consistency, and simplicity in prof...

Details

Refurbished Shanklin CF3 Side Seal Shrink Wrapper

The Shanklin CF3 is a refurbished continuous side-seal shrink wrapper engineered for precision, s...

Details

New Cousins LP2100 Pallet Wrapper w/ 110" Wrap Height

The Cousins LP2100 is a low-profile, semi-automatic pallet wrapper built for industrial performan...

Details

New Cousins LP2100 Pallet Wrapper

The Cousins LP2100 is a low-profile, semi-automatic stretch wrapper engineered for dependable, hi...

Details

New Cousins LP2100 Pallet Wrapper

New Cousins LP2100 Pallet Wrapper

The Cousins LP2100 is a low-profile, semi-automatic stretch wr...

Details

Refurbished BestPack Random 3" Top & Bottom Case Sealer – Side Belt Drive

The BestPack Random 3" Case Sealer is a fully automatic random-size carton sealer built for preci...

Details

New Magnum 2300SDU Case Sealer

New Magnum 2300SDU Case Sealer

The Magnum 2300SDU is a uniform side-drive case sealer engineered...

Details

New Cousins LPSWA, Pallet Wrapper

New Cousins LPSWA Pallet Wrapper

The Cousins LPSWA is a semi-automatic, low-profile pallet wrapp...

Details

New Cousins LP2100 Pallet Wrapper

New Cousins LP2100 Pallet Wrapper

The Cousins LP2100 is a semi-automatic, low-profile stretch wr...

Details

New BetterPack 333, Gum Tape Dispenser, Manual, 06-30" Lengths

New Better Pack 333 Gum Tape Dispenser – Manual, 6" to 30" Lengths

The Better Pack 333 is a manu...

Details

New BetterPack 333H, Gum Tape Dispenser w/Heater, Manual, 06-30" Lengths

New Better Pack 333H Gum Tape Dispenser w/ Heater – Manual, 6" to 30" Lengths

The Better Pack 33...

Details

New BetterPack 555eS, Gum Tape Dispenser, Electronic, 06-45" Lengths

New Better Pack 555eSA Electronic Gum Tape Dispenser – 6" to 45" Lengths

The Better Pack 555eSA ...

Details

New BetterPack 555eSA, Gum Tape Dispenser, Electronic, 06-45" Lengths

New Better Pack 555eSA Electronic Gum Tape Dispenser – 6" to 45" Lengths

The Better Pack 555eSA ...

Details

New Damark Tunnel SZX-34-16-EX

New Damark SZX-34-16-EX Shrink Tunnel

The Damark SZX-34-16-EX is a high-efficiency shrink tunnel...

Details

New Damark B34MP Bundler

New Damark B34MP Bundler

The Damark B34MP is a brand new, high-performance shrink bundler design...

Details

New Matrix TN1212, Bench Scale, 12" x 12" x 12" & SBI-505 Digital Weight Indicator

New Matrix TN1212 Bench Scale – 12" x 12" x 12" with SBI-505 Digital Weight Indicator

The Matrix...

Details

Better Pack 222 Gum Tape Dispenser

The Better Pack 222 is a manual water-activated (gummed) tape dispenser designed for reliable, co...

Details

New Microjet HRP Ink Jet Printhead, 1/2"ph w/CTS III Controller w/Universal Ink Clip

New Microjet HRP Ink Jet Printhead – 1/2" PH w/ CTS III Controller & Universal Ink Clip

The Micr...

Details

Refurbished Damark SMC1620, SA L-Bar Sealer

Refurbished Damark SMC1620 SA L-Bar Sealer

The Damark SMC1620 SA is a refurbished semi-automatic...

Details

New Bel 505 Case Former, Semi-Auto

New Bel 505 Semi-Automatic Case Former

The Bel 505 is a brand new, semi-automatic case former de...

Details

Refurbished Shanklin T81 Tunnel

Refurbished Shanklin T81 Shrink Tunnel

The Shanklin T81 is a refurbished, high-performance shrin...

Details

Refurbished Shanklin T6H Shrink Tunnel

Refurbished Shanklin T6H Shrink Tunnel

The Shanklin T6H is a refurbished, heavy-duty shrink tunn...

Details

New Shanklin T7H Single Chamber Tunnel w/Options

New Shanklin T7H Single-Chamber Shrink Tunnel w/ Options

The Shanklin T7H is a brand new, single...

Details

Refurbished Shanklin T7H Single Chamber Tunnel

Refurbished Shanklin T7H Single-Chamber Shrink Tunnel

The Shanklin T7H is a single-chamber shrin...

Details

Refurbished Shanklin T7XL Tunnel

Refurbished Shanklin T7XL Shrink Tunnel

The Shanklin T7XL is a heavy-duty shrink tunnel engineer...

Details

Refurbished Cousins ORMP-S, Loading Ramp, 48"w x 60" for LP

Refurbished Cousins ORMP-S Loading Ramp – 48" x 60" for LP Turntable

The Cousins ORMP-S is a ref...

Details

New Label Dispenser, Tach-It SH414D

The Tach-It SH414D is a brand new, automatic label dispenser designed for fast, accurate, and rel...

Details

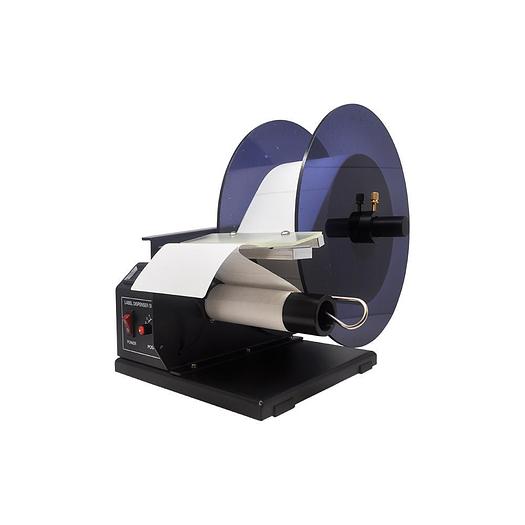

New Label Dispenser, Tach-It SH402TR

New Tach-It SH402TR Label Dispenser

The Tach-It SH402TR is a brand new, semi-automatic label dis...

Details

Refurbished Shanklin CO1231B, Belt Conveyor, 16" x 78"

Shanklin CO1231B Belt Conveyor – 16" x 78"

The Shanklin CO1231B is a reliable belt conveyor desi...

Details

Refurbished Shanklin H2064A, Belt Conveyor, 16" x 78"

Refurbished Shanklin H2064A Belt Conveyor – 16" x 78"

The Shanklin H2064A is a high-quality belt...

Details

New Shanklin TR-CBL-72, Belt Conveyor Infeed For TR2, 16" x 72"L

The Shanklin TR-CBL-72 is a new, factory-built belt conveyor infeed designed for seamless integra...

Details

Refurbished Shanklin TR-CBL-72, Belt Conveyor Infeed For TR2, 16" x 72"L

Shanklin TR-CBL-72 Belt Conveyor Infeed for TR2 – 16" x 72"

The Shanklin TR-CBL-72 is a precisio...

Details

Refurbished Conveyor, Gravity Roller, 8.5" x 10'

This refurbished gravity roller conveyor is built for smooth, efficient product handling across a...

Details

Refurbished Loveshaw LDR/3 Case Sealer,3" T&B,

Refurbished Loveshaw LDR/3 Case Sealer – 3" Top & Bottom Drive

The Loveshaw LDR/3 is a heavy-dut...

Details

New Interpack USA2024SB 2" Case Sealer

---------------------------------------------------------------

Interpack USA2024SB 2" Case Seal...

Details

New Magnum 2300 T-Table 2" Case Forming & Packing System

The Magnum 2300 T-Table is a reliable, high-efficiency case forming and packing system designed f...

Details

Refurbished Shanklin A26A Auto L-Sealer

Refurbished Shanklin A26A Automatic L-Sealer

The Shanklin A26A is a refurbished, automatic L-bar...

Details

New Shanklin T71 Extended Chamber Tunnel w/ Options

New Shanklin T71 Extended-Chamber Shrink Tunnel w/ Options

The Shanklin T71 is a brand new, exte...

Details

New Signode TTX Strapping Machine

New Signode TTX Strapping Machine

The Signode TTX is a brand new, automatic strapping machine en...

Details

Refurbished Little David LD16AX3 Case Sealer 3",T&B

Refurbished Little David LD16AX3 Case Sealer – 3" Top & Bottom Drive

The Little David LD16AX3 is...

Details

Refurbished Clamco Model 120 Combo Shrink System

Refurbished Clamco Model 120 Combo Shrink System

The Clamco 120 is a all-in-one L-bar sealer and...

Details

Cousins Pilot X Low-Profile Semi-Automatic Pallet Wrapper – 4000 lb Capacity

The Cousins Pilot X is a low-profile, semi-automatic stretch wrapper built for durability, precis...

Details

New CRT-1100 Motorized Rotary Accumulation Table – 43" Diameter w/ Casters

New CRT-1100 Motorized Rotary Accumulation Table – 43" Diameter w/ Casters

The CRT-1100 is a mot...

Details